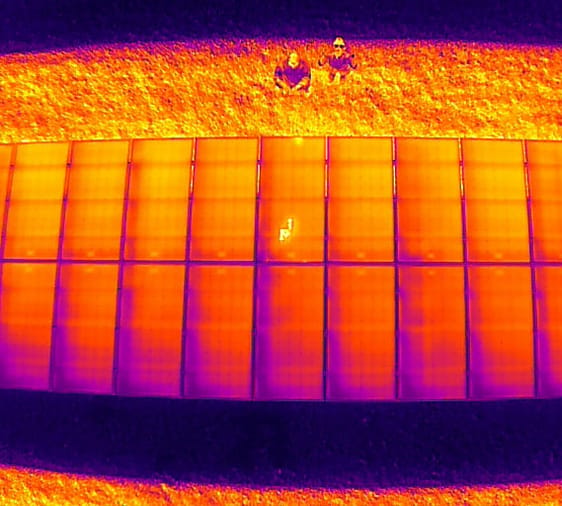

A recent trial at our Onslow Power Station solar farm, using drone technology to capture infrared and high-resolution imagery, successfully identified solar panels with defects.

Steve Lilliss, Senior Manager Asset Management in the Operations Division, was on site while the technology was tested.

“There are some key benefits to using drones and infrared technology,” Steve said.

“At the moment, we conduct solar farm inspections in person on the ground. This is time consuming – for example the Onslow solar farm, which is about 1MW in size with 3,022 panels, takes up to two days with two people to perform visual inspections that only identify obvious damage and do not detect deterioration in performance, for example hot or cold spots. Additionally, our crew can only view from the ground.”

“Using a drone allows us to get a birds eye view, zoom in for high-resolution and capture infrared images in a much shorter timeframe.”

Drones with infrared cameras gather data from collected thermal readings and translate into images. The images captured during the trial identified hot and cold spots on the solar panels – which may mean the panel isn’t working as it should or that it’s reaching end of life.

“We found one damaged panel and another that had not been connected during commissioning,” Steve said. “We were able to pinpoint the exact panels and organise immediate replacement which is a great use of this new technology!

“The drone can identify issues that might not be able to be seen by the naked eye,” Steve said, “and so knowing these potential issues early allows us to plan our asset maintenance and replacement programs more efficiently.

“Additionally, the time taken to survey via drone versus via people on the ground is significant. During the trial, the drone was in the air for about 20 minutes. The initial images were analysed immediately while we were there, with team members able to walk directly to the faulty panels and take action to replace them.

“The further analysis of all panels takes only a few hours and can help us identify loss in performance, or whether cleaning may be needed if pollution has impacted panel output. The outcomes of the report were positive - only 32 of the 3022 panels were identified as having reduced performance. This is considered very minor and results in only a 1.06% de-rating factor on the overall rated output capacity of the solar farm.

“This reinforces that natural washing is effective in Onslow, as we’ve not undertaken any specific washing since it was commissioned. And as we had spare panels onsite, repairs were undertaken in situ.”

“At the moment, we’re using Sensorem for this work,” Steve explained. “But ideally, we’ll be able to train some of our crew up with commercial drone licences and bring inspections in-house in the near future.”